Konkeumatshini wokusika we-laserineenzuzo zabo, ezifana ne-co2 laser, i-Yag laser njl, kodwa kubonakala ngathi iingenelo ze-fiber laser cutting machine zide zigqithise nayiphi na enye i-laser cutting machine.Ukusika i-Fiber laser kuqalile ukufumana ingqalelo engakumbi kwiminyaka embalwa edlulileyo.Nangona kunjalo, izibonelelo zomatshini wokusika i-fiber laser zizise uncedo oluninzi kubavelisi abasebenza ngesinyithi kwihlabathi liphela.Ngophuhliso olukhawulezayo lomatshini wokusika i-fiber laser, iyakwazi ukuziqhelanisa ngokulula kwaye ilungelelanise uluhlu olubanzi lwezicelo kumashishini ahlukeneyo.

Umatshini wokusika iFiber laser uneenzuzo ezininzi.Okokuqala, Umatshini wokusika i-fiber laser unokusebenza ngamandla aphezulu kunye nokusebenza kakuhle kwaye ufanelekile kwiindidi ezininzi zeenkqubo zokusika.

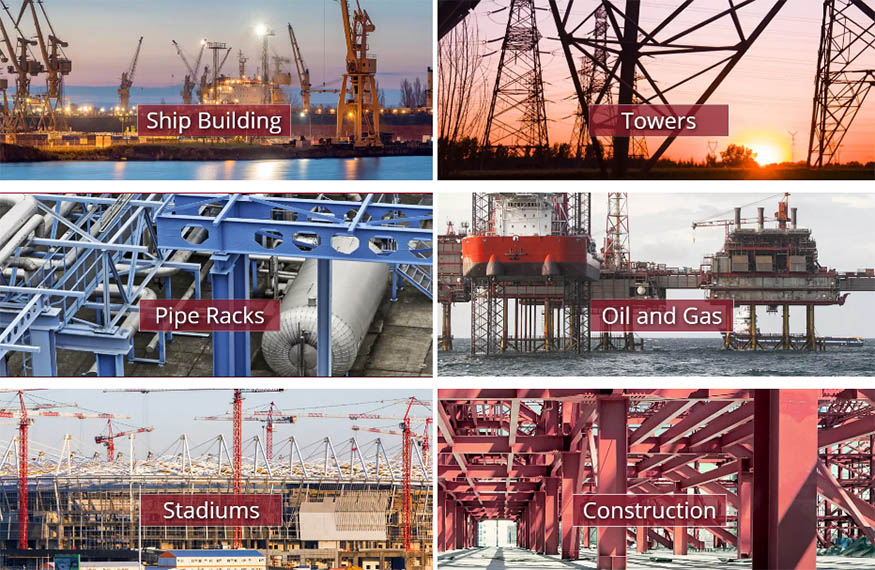

Umatshini wokusika i-fiber laser usetyenziswa ngokubanzi kwi-processing comprehensive processing sheet kwishishini lesinyithi ngenxa yeenzuzo zesiphumo esihle kakhulu sokusika, isantya esisebenzayo sokusika, iindleko eziphantsi zokucwangcisa, kunye neendleko zokugcina.Ibe sisiqwenga sezixhobo zokusika eziyimfuneko kwishishini lesinyithi.Izizathu zokuba kutheni oomatshini bokusika i-fiber laser bethandwa kwimarike yomatshini wokusika isinyithi ikakhulu ngenxa yezi zizathu zilandelayo.

Ukuguquguquka okuphezulu

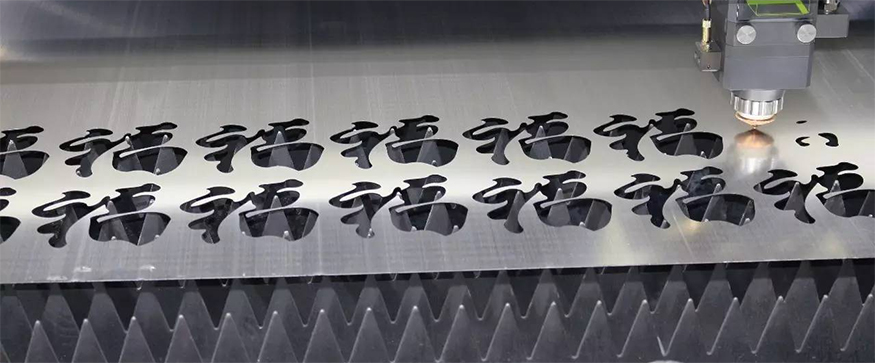

Xa kusetyenzwa ngamashiti esinyithi acekethekileyo, umatshini wokusika we-fiber laser unokuguquguquka okuphezulu ukuqonda ukusetyenzwa okuguquguqukayo.Iyakwazi ukuqhubela phambili ngaphandle kokuqhutyelwa phambili kwesibini kwaye ifaneleke kakhulu kwimveliso enkulu.Umgaqo-siseko wokusebenza we-fiber sheet wase-lase cutter kukukhupha i-laser beam kunye noxinano lwamandla aphezulu kwi-workpiece yentsimbi ukwenzela ukuba inxalenye ifudunyezwe kwaye inyibilike.Kwaye ke sebenzisa i-high-pressure gas ukuvuthela i-slag ukugqiba ukusika, ngoko ke akuyi kubakho burrs kunye neemeko zokuhlaziya.

Ukuchaneka okuphezulu

I-fiber laser cutting machine beam igxininiswe kwindawo encinci kunye nobubanzi obumalunga ne-0.1mm.Ukusika kuchanekile kakhulu kwaye kuhambelana nokusingqongileyo ngokunjalo.

Inkqubo yokusika i-fiber laser ithatha inkqubo yokulawula ngokuzenzekelayo ngokuzenzekelayo, esebenzisa i-non-contact processing ukuqinisekisa ukuba izinto azibonakalisi ngoxinzelelo lomatshini kwaye aziyi konakalisa iziqwenga zentsimbi.

Ezoqoqosho

Kwinkqubo yokusika yendabuko, ukusika i-sheet metal workpiece ngokusisiseko kwenziwa ngokugubungela.Xa imveliso entsha okanye iimilo ezahlukeneyo ze-sheet metal material zitshintshwa, i-mold idinga ukutshintshwa, okwandisa ngokungabonakaliyo iindleko.Ngaphezu koko, akuncedi ukusungula imveliso kwangethuba ukuze wenze ukhuphiswano.

Nangona kunjalo, iumatshini wokusika i-fiber laserinomjikelo omfutshane wokusika wokucutshungulwa.Ukusikwa kunye nokucutshungulwa kwamaqhekeza kunokufezekiswa ngokulula ngokungeniswa kwenkqubo yolawulo lwezixhobo zokusebenza ngoguqulelo lwe-elektroniki lomzobo.Kule meko, umatshini wokusika i-fiber laser unciphise kakhulu umjikelo wemveliso.Kuninzi lwenkampani, ukucutha umjikelo wemveliso kuthetha ukwandisa ukukhuphisana kwenkampani.Ikwaluncedo ekulawuleni iindleko kwaye inokunyusa ixabiso lezoqoqosho.

Oomatshini bokusika i-Fiber laser badlala indima ephambili kwiphepha lesinyithi.Kwaye abaninzi abavelisi be-sheet metal processing baya kukhetha oomatshini bokusika i-fiber laser ukusika amaqhekeza esinyithi endaweni ye-plasma okanye i-co2 laser cutting.

Phakathi kwabakhiqizi abaninzi bentsimbi ye-laser, umatshini wokusika i-KNOPPO fiber laser uthandwa kwimarike.Ukutyhubela iminyaka yophuhliso, i-KNOPPO inomthamo wonyaka wokuvelisa we-3000 oomatshini bokusika i-fiber laser.Umatshini wokusika i-fiber laser we-KNOPPO usetyenziswa ngokubanzi kumatshini ochanekileyo, iinxalenye zemoto, ikhitshi kunye ne-hardware yokuhlambela, i-elektroniki kunye nombane, kunye namanye amashishini amaninzi.

Ixesha lokuposa: May-21-2021